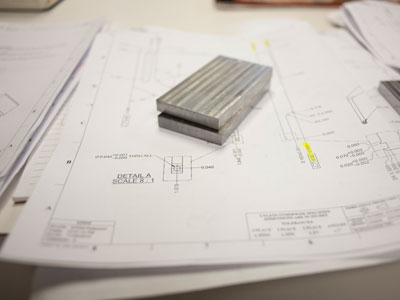

Our Shop

Equipment & Facilities

JBJ Precision Industries upholds it commitment to reliability, precision, and accuracy on a global scale. An Ingersoll-Rand Screw Compressor with Dryer System cleans and drys the air through out the facility.

The 10,500 square feet state-of-the-art facility is fully heated/air conditioned with a complete dust collection system that keeps the area clean and machine technology free of grinding and machine dust.

Facility Information

EQUIPMENT INFORMATION

Shop Floor Space:

10,500 square feet, fully heated/air conditioned facility. Complete dust collection system to keep area clean and machine technology free of grinding and machine dust. Ingersoll-Rand Screw Compressor with Dryer System for clean and dry air through out the facility.

CNC Milling Machines:

- Bridgeport EZ Trak English/Metric two axis fully tooled. (4 Units)

- Haas VF-3 Fully Tooled with complete options including Fourth Axis (1 Unit)

- Haas VF-1 Full Tooled with complete options including Fourth Axis (1 Unit)

- Haas Super VF 2 High Speed CNC Machining full tooled (3 Units)

- Haas Mini Mill Full tooled

- Haas Super Mini Mill Fully tooled

- Hass CNC Lathe Full Tooled

CNC Sodic Wire Cut EDMAQ 325L:

- 9” thickness capability tooled with Hirschmann Tooling System, dimensional tolerancing within .00005”.

CNC Sodic Wire Cut Mark EX EDW 280L:

- 6” thickness capability tooled with Hirschmann Tooling System, dimensional tolerancing within .00005”.

Agie Elox Mondo 2 Sinker EDM:

- CNC Sinker EDM 12 x 12 x 12 Full 3R Tooling and vast assortment of fixturing. .0005” Tolerancing.

Mitsui Surface Grinders (2 Units):

- Tooling to include Harig grind fixtures, radius attachments and various wheels with tolerancing within .00005”. One manual and one fully automatic.

Hardinge Toolroom Lathe (2 Units):

- Model HLV-EM with English/metric capabilities, full range of collets, taper attachment and support tooling.

Ezpath CNC Lathe:

- 14” swing with full range of collets, chucks and support equipment.

Welding/Fabrication Equipment:

- Miller Mig Welder

- Miller Tig Welder

- Weldsale Welding Table with all clamps for precise welding and fabrication

- Airflow system to eliminate welding fumes and smoke

General Scanning Inc. Laser Marker:

- Intricate marking of tooling as well as micro machining of thin metals and plastics. Configured with latest software for import of logos as well as various fonts required by customers.

Trusted Results

QUALITY CONTROL

Complete quality control program in place including documentation and the following equipment and tools:

Electronic Heidenhain

Depth Gage .000005” r/o

.0100” - .750” Gage Pin Sets (Also incremental sets of various sizes)

12” & 18” Height Gages

English & Metric

Complete range of test indicators .001” - .00005” (12 each) Including Metric

Brown & Sharp Micro-Hite

24” Computerized Height Stand with print out capabilities

TESA-Hite 400

24” Computerized Height Stand

Brown & Sharp CMM

Full range of probes, utilities and printer. Fully computerized.

0” - 6” Micrometer Sets (2 sets)

0” – 12” Micrometer Set (1)

0100” through 4.000” Gage Block Sets (6 sets)

24 X 36 Surface Plates (3 each)

Numerex CMM

4’ x 4’ area and full tooling to include range of probes and also Vision System with full computer system. With updated Quara-Chek 300 system

Nikon

Boom Stereo Scopes with Fiber Optics on each.

Full Design Capabilities

ENGINEERING

Master CAM systems for wire cut EDM and CNC milling and turning machine (5 stations)

3D Modeling System

AutoCAD Pro-E and Solid Works. (4 stations)

Capabilities of email file transfers with high-speed Internet connections 24 hours a day

All software is licensed and audited by independent service annually